Key Challenges

The company faced three key challenges. Firstly, they were keen to develop innovative products, particularly for the golfing sector, but needed help assessing feasibility and market potential. Manufacturing presented another hurdle, with the need to optimise product designs and streamline processes to scale production efficiently without compromising quality. Additionally, as their product range evolved, they required a more robust marketing strategy and better tools to enhance customer engagement, particularly to increase customer enquiries and improve product guidance.

New Product Development

STRIDE’s involvement began with product development. They supported Sports Metals in the early stages of a new product for the golfing industry, conducting market research and feasibility studies to assess its viability. Collaborative strategy sessions helped refine the development process and align the design with market needs. Although discussions with The University of Plymouth were explored for commercial opportunities, STRIDE’s primary focus remained on planning for future business models and laying the groundwork for further innovation.

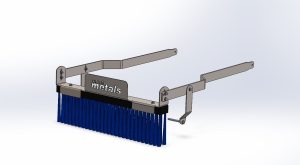

Reverse Engineering

Manufacturing efficiency was tackled through reverse engineering. STRIDE facilitated the use of 3D scanning technology to capture detailed designs of Sports Metals’ existing lawnmower product range. This was followed by the creation of CAD (Computer-Aided Design) models, which allowed for accurate replication and modifications of the products. The process not only enabled the company to streamline production but also opened doors to new manufacturing opportunities. STRIDE extended their support by providing templates and guidelines, allowing Sports Metals to apply reverse engineering techniques across their entire range, offering greater flexibility and scalability in production.

Marketing Support

In marketing, STRIDE worked with Sports Metals to refine their strategy in alignment with future growth plans. This included exploring options for hiring marketing interns and subcontractors, as well as fostering partnerships with freelance marketers. STRIDE also supported customer engagement by creating instructional content, such as manuals and animated assembly videos. These resources were hosted on the company’s website, reducing the need for customer support, and making the purchasing process smoother and more intuitive.

Resource Planning

STRIDE was also able to help Sports Metals with operational support. After identifying Odoo as the most suitable Enterprise Resource Planning (ERP) system for the company, STRIDE supported with its implementation. The software streamlined stock management and automated order processing, significantly enhancing the company’s efficiency. Furthermore, STRIDE supported the automation of part numbers for Sports Metals’ products, enabling better stock management and helping to set minimum order quantities, ensuring smoother operations and better inventory control.

Greater Efficiency

Through strategic product development, enhanced manufacturing capabilities, and improved marketing and operational processes, Sports Metals has positioned itself for long-term growth and greater efficiency. STRIDE’s support has helped the company refine its product offerings, optimise its internal operations, and better engage with customers.